These are scans from the first knife I ever made. It was also the first time I used a forge. The blade is random pattern damascus, forged from high and low carbon steel and etched with hot sulfuric acid. Moose horn handle with brass pins.

I didn't have access to a forge lately, so I bought japanese damascus steel stock instead and ground a blade from it:

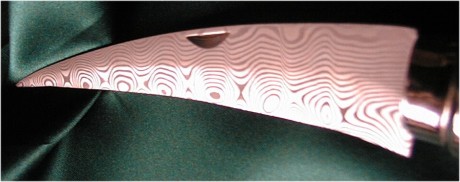

It obviously follows the Opinel-Type pattern and the locking/folding mechanism is from one of their knives, too. You can spot the pattern on the blade by clicking on the picture below:

I've tried something very practical: stainless damascus steel from Damasteel AB, Sweden. I chose this steel to compete with modern, easy-to-maintain stainless knives. I thought such a steel would suit a luxurious kitchen knife which my parents would be happy to get as a present.

I used brass pins, african walnut and a bronze bolster. The pin inside the bolster is damascus steel as you can see by clicking on the detail below:

Time constraints kept me off my next project for quite some time, but I finally got my second Opinel-type knife done. I used some left-over steel from the kitchen knife above and used it on a slim and pointy pattern:

You can have a look at the details of the damascus pattern on the other side of the blade by clicking on the picture below:

With some more leftovers from the Damasteel piece, I collaborated with Wytse Sikkema, a Dutch knife-maker I got to know here in Houston, Texas to make this fine folder:

The scales are made from finest Wenge wood and look fantastic. These crude images don't do this incredible wood finish justice at all.